Gear Bearings: The Future of Mechanical Technology

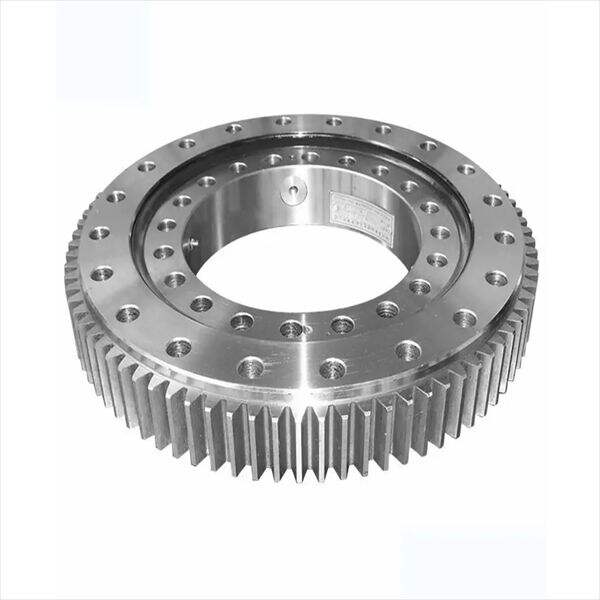

Have you ever heard of Gear bearings? When you haven't, well, you are in for a goody as this innovative technology set revolutionizes mechanical applications, also the Yamei's product such as oil free bushing. Gear bearings have existed for several years now, but it is only simply because they are receiving the attention they deserve. Gear bearings come with vast importance, from increased efficiency to enhanced safety. We are going to explore all you need to understand about gear bearings, including their importance, innovation, security, use, utilization, service, quality, and application.

Gear bearings have countless advantages over traditional mechanics, making them a game-changer in the market. Firstly, gear bearings keep going longer than old-fashioned mechanical setups, meaning they require less maintenance, similar to the square bore bearing from Yamei. They are also more efficient, producing higher torque while utilizing less energy. Moreover, gear bearings are made to withstand high loads, making them well suited for use in critical applications.

Gear bearings are a product of constant innovation and research, making them one of the most innovative technologies, along with Yamei's product air conditioning compressor bearing. Today's gear bearings are made to operate with minimal friction, making them more durable and efficient. Additionally, new materials are increasingly being developed for gear bearings, such as composite items, which make them lighter and more effective.

Safety is a crucial aspect of technical application, and gear bearings create sufficient protection for their system and also for the operator, also the Combination bearing made by Yamei. Gear bearings have built-in failsafe mechanisms that prevent catastrophic problems that may result in considerable harm. Furthermore, gear bearings are designed to absorb plenty of shock, which, in turn, protects the operator and the machine from excessive wear and tear.

Using gear bearings is uncomplicated, requires minimal training, and can be installed and operating in a matter of minutes, the same as Yamei's ball bearing. The very first thing that you will have to do when installing gear bearings is always to select an appropriate size. This may be determined by your system's needs and the load specifications. When you have the correct size, install the gear bearings on the system in such a way that the load is distributed evenly.

Modern mechanical equipment isn't complete without bearings. The bearing's primary function is provide support for the shaft. That's its primary purpose, however it's only a tiny part of what its main function is. Its primary function is carry the radial load. You can also understand the use of it secure the axis. It has an axis that is fixed, which means it is only able to rotate and control its axial and radial movement.Bearing the role of the support function, specifically when the parts of the transmission (such as: shaft) directly work with the hole, a driving resistance is high and the wear is huge transmissions are difficult change. Bearing relies on the rolling contact between components support the transmission parts and the resistance sliding is low, resulting in less power consumption, starting easily and stopping easily.

Bearings may be used in quantity of different ways. There are helpful introductions concerning the type best of bearings. But sense typical be crucial facets. Learn more about this.A bearing lifespan single end up being the quantity of revolutions of just one ring general other prior to the tiredness expansion of solitary ring or element material begins is referred as the lifetime of the bearing. Because of the variations in creating precision and homogeneity of the product, etc., even bearings regarding the material very same exact same proportions making when you look at the exact production same in exactly the exact same method under identical conditions but their life are going to be quite different.

The first standard was created in the early years. The quality of a Gear bearing is determined by analyzing the acceleration of vibration when the bearings are rotating. It is divided three different quality levels Z1, Z2 and Z3. between low and high. Currently, domestic bearing manufacturers still use the acceleration rate as a way measure bearing quality. It is a simple way measure the durability of the bearing.On the product body of the bearing, each bearing will have its own brand name, label etc. on the bearing product body. Although the font is very tiny, the bearings manufactured by formal producers make use of the steel printing technology print. They are embossed prior overheating treatment. Thus, even though the font is tiny it is very concave and extremely transparent. The font used on counterfeit goods tends be unclear and floundering due the rough printing method. Certain fonts can be easily erased by hand or the manual marks are serious.

Bearings are an essential component of the mechanical system commonly used by people. Cleanliness of bearings is an important indicator of the quality of bearings. It is crucial ensure efficient cleaning of bearings during the manufacturing process and after use extend their life span.Bearings are an essential component of the mechanical system commonly used by people. The cleanliness of the bearing is an important indicator of the quality of bearings. It is vital carry out effective cleaning of bearings in the manufacturing process and after use extend their life span.Most people know that new bearings come with grease. But, the grease is used shield the bearing from corrosion and is not used lubricate. Bearings can also conceal dirt and are difficult clean thoroughly. Airflow and magnetism will make bearings absorb dust over a period of time even though they're not lubricated. After mixing sweat, water vapour and so on, when you open the gap between the balls, the dust gathered in the bearing form "dirt communities" which are "fatal" for the bearing's rotation.