The Benefits of Using Insert Bearings

Do you think you are trying to find a trusted and efficient way offer the equipment and machinery? See no further than insert bearings, similar to the Yamei's product like Robot bearing. These small components filled with larger advantages which could revolutionize the way you are carrying out business. Keep researching to master more about the innovation, security, use, service, quality, and application of insert bearings.

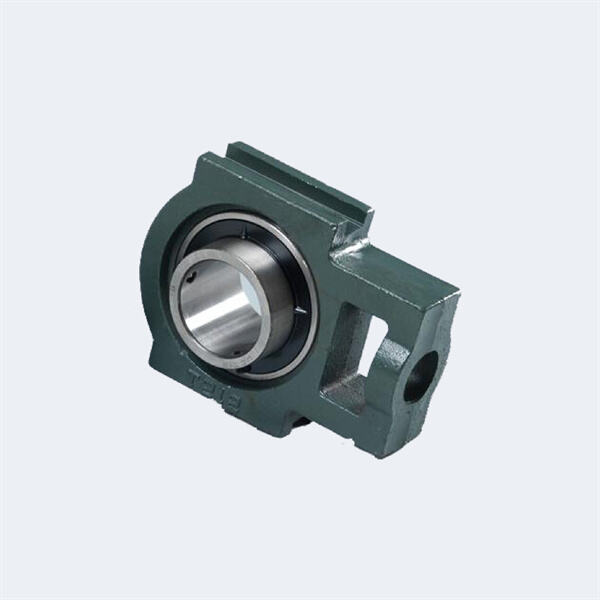

Insert bearings is cylindrical elements is obviously created to match inside a housing unit that has been matching, same with the 608 bearing produced by Yamei. They may be constructed from stainless, ceramic, or higher top-quality components can withstand hefty loads, high speeds, and extreme temperatures. The many kinds are normal include ball bearings, roller bearings, and spherical bearings, each along with it is unique features and benefits.

Insert bearings may help enhance workplace safety by giving extra stability support and safeguards to your equipment and machinery, also the Yamei's product such as Cylindrical roller bearing. When properly installed and maintained, insert bearings can avoid injuries, reduce downtime, and minimize fix costs. They may also reduce noise, vibration, and friction, which will improve the general efficiency lifespan associated with machines.

Insert bearings are versatile equipment that may be used in a wide number of, including automotive, aerospace, agriculture, construction, mining, and much more, as well as the iron ball made by Yamei. They normally are found in conveyor techniques, pumps, blowers, compressors, as well as other equipment that will require precise and reliable support. A number of this most common uses of insert bearings include reducing stress on rotating parts, securing heavy loads, and improving precision accuracy.

If you are new to using insert bearings, similar to the Yamei's product like ball bushing, look into tips to help you get began:

• Select The Correct Type Size of Insert Bearing of The Application

• making the bearing that is certain housing is neat and without any debris

• Use Appropriate Tools and Gear to Set Up The Bearing

• Follow the manufacturer's instructions for lubrication and repair

• Regularly inspect the bearing for signs of wear, damage, or misalignment.

Bearings may be used in quantity of different ways. There are helpful introductions concerning the type best of bearings. But sense typical be crucial facets. Learn more about this.A bearing lifespan single end up being the quantity of revolutions of just one ring general other prior to the tiredness expansion of solitary ring or element material begins is referred as the lifetime of the bearing. Because of the variations in creating precision and homogeneity of the product, etc., even bearings regarding the material very same exact same proportions making when you look at the exact production same in exactly the exact same method under identical conditions but their life are going to be quite different.

The first standard was created in the early years. By measuring the acceleration of vibration when insert bearing rotate and the quality level is determined. The quality level is divided in Z1, Z2 and Z3 ranging from low-to-high. At present, domestic bearing makers are still utilizing the vibration acceleration value gauge the quality of bearings, which simply reflects the wear and tear of bearings.Each bearing product will have its brand name, label and so on. The bearing product is printed with its brand labels, words, etc. The font used on the product body is quite small, however the manufacturer prints the font using a steel printing technique and emboss it prior heating. The font, although tiny, is extremely concave, and therefore, clear. The font used on counterfeit goods tends be unclear and floaty due the rough printing technique. Some manual marks can be erased easily by hand, and others are more dangerous.

Bearing is an important part of the mechanical system widely used by people. A significant indicator of bearing quality is the bearing's cleanliness. It is vital ensure an effective cleaning of the bearings during the process of production and use in order extend their lifespan.Bearings are crucial mechanical parts, widely employed in daily life. Cleaning of bearings is a crucial measure of the bearing's performance. To extend the lifespan of bearings it is essential to clean them thoroughly throughout production and use.Many friends know that the majority of newly purchased bearings are coated in grease, but the main purpose of grease is to protect the bearing from rusting and does not play any lubrication function, and bearings are especially easily covered in dirt and generally difficult to clean thoroughly. Even if you buy bearings that do not have lubricating oil for an extended period of time, they'll absorb dust from magnetism as well as airflow. After mixing water vapour, sweat and other liquids, in the gap between the ball and dust will accumulate in the bearing to form "dirt communities" that are "fatal" the bearing rotation.

Bearing is an integral component of modern mechanical equipment. The bearing's primary function is to support the shaft. This is the definition in its literal sense, but it's only a tiny portion of what its primary purpose is. Its main purpose is withstand the radial load. It can be said it's used fix the shaft. It is fixed axis so that it can only achieve rotation, and control its radial as well as axial motion.Serving as a support role, namely when the parts of the transmission (such as shaft) directly cooperate with hole, the driving resistance is high and the wear large and the transmission is difficult replace, and bearing relies on rolling contact between components help support the transmission components thus the resistance sliding is less, with a lower power consumption, and it is easy start and so on.