A safe and innovative way to get to know the Yamei sphere bearing

Opening statement.

Do you know anything about eyeglasses or contact lenses? Optical axis is the deciding factor this short piece of info and outlines its benefits, advancements, applications, safeguarding guidelines.

The imaginary line through the center of this lens, which separates it into two equal parts, is also known as the optical axis. This line helps in the optical focus on the object, it helps in the direction of light entering the lens. Optometrists can prescribe clear vision corrections by identifying the career path of the optical axis. If you want to get the best visual experience and keep eye health, you need to know how to calculate the Yamei spherical bearing.

Measurement was made faster, simpler, and safer with the advent of automated tools. Optical axis measurement machines are noninvasive and give precise information in a matter of seconds. This innovation has transformed the eyeglass and contact lens manufacturing industries. The Yamei sealed bearings machines collect the exact data that enables manufacturers to create individualized lenses that improve vision impairments.

Optical axis measurement machines are safe because they can produce accurate results without testing. Work is noninvasive and there is no risk of infection, harm, or complications. After a dimension optometrists prescribe lenses that are customized to meet user requirements and enable effortless and clear vision. Important remember that a regular measure on the oxygen aches reads the risk of attention problems and opportunity of a creative experience with Yamei bearing ball deep groove.

A patient is positioned in front of a computer machine that uses a camera to measure the optical axis using a light beam, resulting in non-invasive measurements. The Yamei cylinder roller bearing device records the data and analyzes it with precision. Artist prescription for corrective lenses is based on the information provided by the optometrist in-patient. It's easy, quick, and secure. Optical axis is becoming more important for detecting and correcting visual impairments, and it is becoming more important in routine operations.

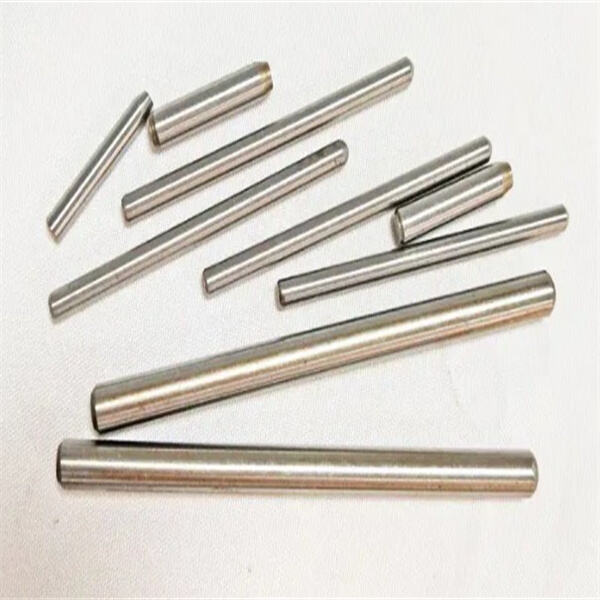

Bearing is an important part of the mechanical system widely used by people. A significant indicator of bearing quality is the bearing's cleanliness. It is vital ensure an effective cleaning of the bearings during the process of production and use in order extend their lifespan.Bearings are crucial mechanical parts, widely employed in daily life. Cleaning of bearings is a crucial measure of the bearing's performance. To extend the lifespan of bearings it is essential to clean them thoroughly throughout production and use.Many friends know that the majority of newly purchased bearings are coated in grease, but the main purpose of grease is to protect the bearing from rusting and does not play any lubrication function, and bearings are especially easily covered in dirt and generally difficult to clean thoroughly. Even if you buy bearings that do not have lubricating oil for an extended period of time, they'll absorb dust from magnetism as well as airflow. After mixing water vapour, sweat and other liquids, in the gap between the ball and dust will accumulate in the bearing to form "dirt communities" that are "fatal" the bearing rotation.

The standard was developed in the early days. Through measuring the acceleration of vibration when Optical axis spin and the quality level is determined. The quality level can be divided in Z1, Z2 or Z3 from low-high. In the present, most domestic bearing makers still use the acceleration measurement to assess the quality of their bearings. This simply measures the bearing's fatigue life.Every bearing item will have its brand name, label, etc. The bearing product is printed with the brand's words, labels, etc. Even though the font is small, products manufactured by manufacturers who are formal use steel printing technology print. They are embossed prior overheating treatment. This means that even though the font is small however, it is extremely concave and very well-defined. The fonts on counterfeit products is often sloppy and floating due the printing process that is rough. Some can even be easily erased with a hand, or marks made by hand are very serious.

Modern machinery isn't fully functional without bearings. The bearing's primary function is support the shaft. This is its actual meaning, however it is just a small portion of what its primary goal is. Its purpose is help support the radial load. It is also possible understand the purpose of using it stabilize the axis. It is fixed axis so it's able achieve rotation, and control its radial and axial movements.Bearings are a crucial component. If the transmission parts (such as shafts) are directly in contact with the hole the driving resistance and wear is excessive, and the transmission is not easy change and the bearing is dependent on rolling contacts between components support the parts of the transmission. This leads a low sliding resistance, lower power consumption and easier starting.

Bearings are utilized in variety of different ways. There are number of relevant guides for choosing the type and brand of bearings. But, common sense will be crucial factor. Know more about it.The duration of bearing is the number of rotations one band makes relative its counterpart before the first expansion in fatigue occurs within one ring material or rolling element. Because of differences in precision of manufacture, material homogeneity, etc. even bearings made from the same material, identical size, and manufactured in the same production batch under the exact same conditions, their lifespans will be extremely different.