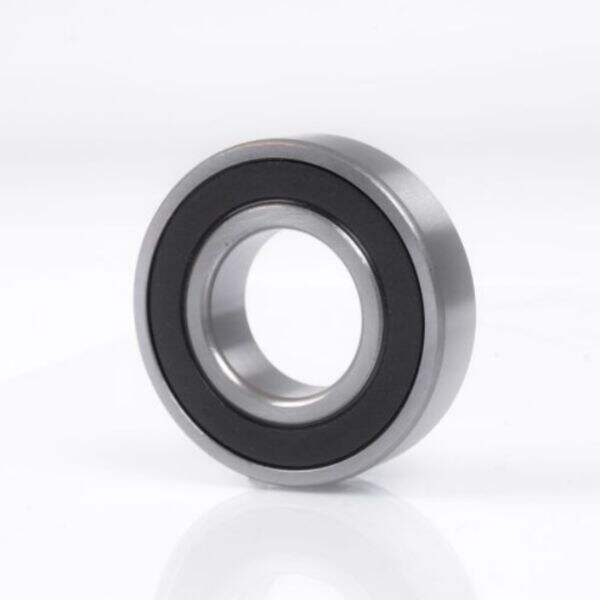

Understanding the 6301 Bearing: Your Ultimate Guide.

Are you familiar with the 6301 bearing? It might sound complicated; however, it is a simple but important part of. We will discuss the Yamei advantages, innovation, safety, usage, and application of this bearing.

The 6301 bearing was commonly put due to the Yamei advantages. Firstly, this has a high load capacity, that means it could bring heavy loads. Next, it has a lower friction, which assists reduce wear and tear. Finally, it's a very lifespan long making it a cost-effective option ball bearing equipment.

The 6301 bearing has encountered several Yamei innovations the ages. One of several present thrust bearing advancements use of ceramic balls in the bearing. Ceramic balls have superior resistance and hardness to wear and tear, creating them a perfect material.

Safety is actually a critical consideration using any Yamei equipment, and the 6301 bearing was no exception. When used properly, this axial bearing is safe. However, it is essential to adhere to the utilization directions and abide by safety guidelines. Failure to do this can lead to accidents and injuries.

The 6301 bearing is commonly utilized in various Yamei equipment, including motors, pumps, and gearboxes. It plays an essential job enabling the smooth and efficient operation of machines. Whenever deploying this pillow bearing it's important to make sure it is properly installed and maintained.

Bearings are crucial mechanical parts, widely utilized in our daily lives. Bearing cleanliness is an important measure of the bearing's performance. It is crucial to carry out an effective clean of bearings throughout their production and use in order extend their life span.Bearings are important mechanical component, extensively used in the living environment. Cleaning of bearings is a crucial measure of the bearing's performance. To extend the life of bearings it is vital to wash them thoroughly throughout production and usage.A majority of people are aware that all new bearings come with grease. But, the grease is used shield the bearing against corrosion, and does not serve as lubrication. Bearings also tend to cover up dirt and are difficult clean thoroughly. Even if you buy bearings with no lubricating oil, over many years, they'll collect dust because of magnetism and airflow. After mixing water vapour, sweat and other liquids, in the gap between the ball and the dust gathered in the bearing form "dirt communities" which can be "fatal" to the bearing's rotation.

Bearings are found in variety of other ways. You will find number of relevant guides for choosing the kind as well as the brand name of bearings. Nevertheless, typical sense could be component important. Discover more about any of it.The duration associated with the 6301 bearing will be the number of turns bands makes general its counterpart prior first fatigue expansion occurs in solitary band product or rolling element. Due variations in precision of make and product homogeneity. also bearings made from similar material, related to same dimensions, making in the exact same batch underneath the particular exact same conditions but their life will likely be completely different.

Bearing is a crucial component of modern-day mechanical equipment. Its primary purpose is support the shaft. This is the literal meaning, but it's only a tiny portion of what its primary purpose is. Its essence is help support forces that are radial. You can also understand the purpose of using it fix the 6301 bearing. It's fixed so that it is able only achieve the desired rotation and also control its radial as well as axial motion.Bearing the role of a support role, namely when the parts of the transmission (such as: shaft) directly collaborate with the hole, the driving resistance is significant and the wear is huge transmissions are difficult change, and bearing relies on the rolling connections between components for support of the transmission parts which means that the sliding resistance is less, with a lower energy consumption, it can be started easily or even starting easily.

This standard was initially developed. The bearing's quality is determined by measuring the acceleration of vibration as the bearings are rotating. The quality levels are divided in Z1, Z2 or Z3 from low-to-high. At present, many domestic manufacturers still use the acceleration value as a way assess the quality of their bearings. It's a way of measuring the wear and tear of the bearing.The bearing product body each bearing will bear its own label, brand name and label. on the surface of the bearing. The font used on the bearing product body is quite small, however the official manufacturers print it using the steel printing process and emboss the designs prior heating. The font, despite being tiny, is extremely concave and, consequently, clear. The font on counterfeit products tends be fuzzier and floaty due the printing process that is rough. Certain manual marks are removed easily with a hand, however, others can be more severe.