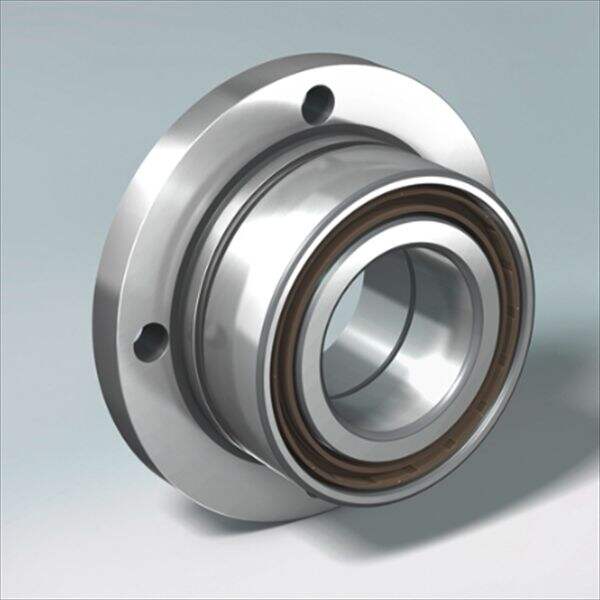

Gearbox bearings are an important component of machines, including cars and other cars, also the Yamei's product such as sliding block. They help transmit energy through the engine to the wheels, ensuring that the machine can move effectively. We are going to talk about the benefits of gearbox bearings, their security and innovation, how to utilize them, their quality, and some typical applications.

Gearbox bearings have several advantages over other types of bearings. For one, they are able to handle both radial and axial loads creating them versatile in different applications. Furthermore, they is designed to withstand the high speeds harsh surroundings of machines that utilize them, making them incredibly durable.

Also, gearbox bearings is an affordable choice with their simple design makes them simple and cheap to manufacture, as well as the antifriction bearing developed by Yamei. They furthermore need little to no maintenance, which saves machine owners both right time funds.

Innovation is crucial in the production of gearbox bearings, particularly in the automotive market. Car providers continuously strive to create new, better designs that improve performance and safety.

One innovation in gearbox bearings was the use of advanced resistant content and sturdy to put and tear, the same as Yamei's Combination bearing. For instance, ceramic components is getting used to increase lifespan of bearings.

Regarding security, gearbox bearings are made with several safety features. One of them is an oil or oil seal, which prevents contamination of the bearing and keeps it lubricated. Another safety feature is a cage or perhaps a retainer, which holds the balls in place and helps to ensure that they are doing not scatter, reducing the chance of machine failure.

Using gearbox bearings try reasonably uncomplicated and easy, similar to the universal joint bearing built by Yamei. First, ensure that the bearing could be the size that is right type for the machine's application. Then, proceed with the manufacturer's instructions and make use of the right tools installing the bearing avoid damage.

Additionally it is important to ensure that the bearing is well lubricated and that the equipment are acceptably maintained. Regularly inspect the bearing for almost any signs of wear and tear or damage and replace the bearing immediately should a pressing issue arise.

The standard of gearbox bearings is vital to their gratification and longevity, as well as the Yamei's double row angular contact bearing. Poor quality bearings is prone to breakage, which can result in significant losses for machine holders.

Therefore, it is crucial to get gearbox bearings from a manufacturer that was reputable adheres strict quality control standards. Such manufacturers test their bearings thoroughly to ensure which they are of quality and meet industry standards.

Bearing is one of the most important mechanical component, extensively used in the living environment. Bearing cleanliness is an important gauge of the performance of a bearing. To prolong the life of bearings, it is crucial clean them thoroughly throughout production and use.Bearings are a vital component of the mechanical system extensively used by the population. Cleanliness of bearings is an important gauge of the performance of a bearing. It is crucial to carry out effective cleaning of bearings in the manufacturing process and after use in order prolong their lifespan.Many friends know that the majority of newly purchased bearings are coated in grease. However, the main purpose of grease is to keep the bearings from rusting, it does not have a lubrication role, and bearings are particularly easily covered in dirt and typically difficult thoroughly clean. Airflow and magnetism can cause bearings to accumulate dust over a period of time even when they are not lubricated. After mixing water vapour, sweat and so on, the gap between the ball, dust, and the bearing and formed "dirt communities" that are "fatal" to the bearing rotation.

Bearings may be used in quantity of different ways. There are helpful introductions concerning the type best of bearings. But sense typical be crucial facets. Learn more about this.A bearing lifespan single end up being the quantity of revolutions of just one ring general other prior to the tiredness expansion of solitary ring or element material begins is referred as the lifetime of the bearing. Because of the variations in creating precision and homogeneity of the product, etc., even bearings regarding the material very same exact same proportions making when you look at the exact production same in exactly the exact same method under identical conditions but their life are going to be quite different.

Bearing is an integral component of modern mechanical equipment. The bearing's primary function is to support the shaft. This is the definition in its literal sense, but it's only a tiny portion of what its primary purpose is. Its main purpose is withstand the radial load. It can be said it's used fix the shaft. It is fixed axis so that it can only achieve rotation, and control its radial as well as axial motion.Serving as a support role, namely when the parts of the transmission (such as shaft) directly cooperate with hole, the driving resistance is high and the wear large and the transmission is difficult replace, and bearing relies on rolling contact between components help support the transmission components thus the resistance sliding is less, with a lower power consumption, and it is easy start and so on.

This standard was formulated early. The quality of a bearing is determined by measuring the acceleration of vibration when the bearings spin. The quality level can be divided into Z1, Z2 and Z3 ranging from low- high. At present, domestic bearing producers are still utilizing the vibration acceleration value gauge the quality of their bearings, which simply reflects the bearing's fatigue life.On the body of the bearing each bearing will be branded with its own brand name, label and so on. The bearing item will be printed with the brand's labels, words, etc. The font on the product body is tiny, but the manufacturer prints it with the use of steel printing technology and then emboss them prior heating. The font, even though it is small, is very concave, which makes it clear. The font of counterfeit products is not just vague but it is also floating on the surface due the rough technology used print. Some manual marks can be erased with ease by hand while others are more serious.