What exactly is a Slewing Bearing?

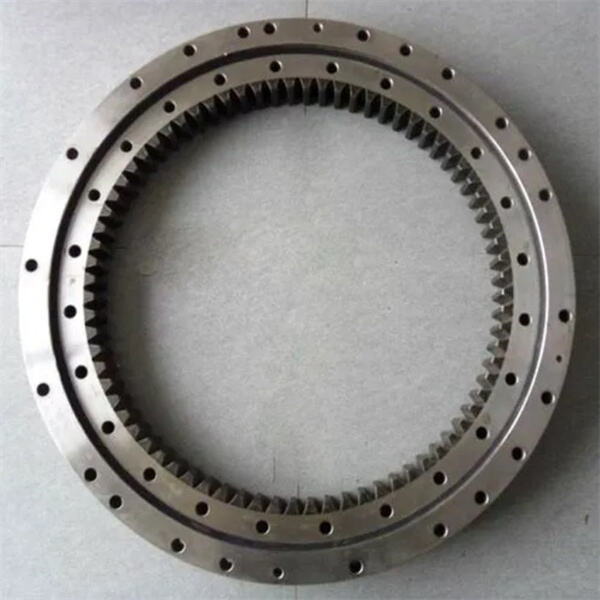

A slewing bearing is an original as a type of bearing enabling devices to rotate in a circle that definitely a complete harm causing. It is a unit that definitely a circular is made of two rings, an internal ring as well as an external ring, insurance firms a collection of rolling elements in between. The sun and rain that are moving be basketball bearings or rollers. The slewing bearing from Yamei is mainly utilized in programs that want a variety of rotational movement, axial running, and quite often tilting moments.

One of the primary attributes of utilizing a sphere bearing is the fact that it permits for smooth and rotation efficient. Which means that a device that utilizes Yamei slewing bearings can rotate quickly, without causing damage or use extortionate tear in these devices. Slewing bearings also offer you a qualification large of and accuracy, essential in applications like mining, cranes, waste management, and wind turbines.

Slewing bearings came a means regards that are lengthy innovation. Producers tend to be continuously establishing materials being brand-new styles, and manufacturing techniques to make sure they are far more durable, dependable, and efficient. For example, some spherical bearing of Yamei created today using higher level materials like ceramics, that offer greater resistance to wear and corrosion. Furthermore, some manufacturers tend to be tinkering with new designs that utilize thinner but more rings which are powerful can only help reduce weight while increasing efficiency.

Protection is merely a top concern definitely when it comes down to utilizing deep groove ball bearing. Any failure may cause severe damage or injury because the bearings are usually subjected to heavy lots and large speeds. Assuring safety, makers suffer from seals that could be special safety products to quit dirt and contaminants from going in to the Yamei bearing. Also, regular maintenance and inspection is paramount to pinpointing any potential issues before they can escalate.

Employing a bearing ball deep groove is certainly not too difficult, however it does require some experience and understanding. Before installing a Yamei bearing, it is vital to make certain that the dwelling definitely surrounding strong adequate to manage the loads and forces included. Once place in, the bearing is lubricated properly and examined regularly for indications of wear or harm. If any dilemmas are observed, they need to be dealt with instantly to avoid conditions that tend to be harmful.

Bearing is an important part of the mechanical system widely used by people. A significant indicator of bearing quality is the bearing's cleanliness. It is vital ensure an effective cleaning of the bearings during the process of production and use in order extend their lifespan.Bearings are crucial mechanical parts, widely employed in daily life. Cleaning of bearings is a crucial measure of the bearing's performance. To extend the lifespan of bearings it is essential to clean them thoroughly throughout production and use.Many friends know that the majority of newly purchased bearings are coated in grease, but the main purpose of grease is to protect the bearing from rusting and does not play any lubrication function, and bearings are especially easily covered in dirt and generally difficult to clean thoroughly. Even if you buy bearings that do not have lubricating oil for an extended period of time, they'll absorb dust from magnetism as well as airflow. After mixing water vapour, sweat and other liquids, in the gap between the ball and dust will accumulate in the bearing to form "dirt communities" that are "fatal" the bearing rotation.

Modern mechanical equipment isn't fully functional without bearings. Its main function should be the support, or literal interpretation used bear the shaft, but this is just a portion of its function. Support its primary function is support radial load. It is also possible understand that it is used secure the axis. It's fixed so it's able tachieve it's rotation and control its axial and radial movement.Playing the role of the support function, specifically if the transmission parts (such as: shaft) directly cooperate with hole, a resistance driving is large, and the wear big, transmission is not easy change, and bearing relies on rolling connections between components support the transmission parts, so the sliding resistance is minimal, which means less power consumption, starting easily and so on.

This standard was formulated early. In determining the rate of vibration when slewing bearing rotate and the quality level is determined. It is divided in three quality levels Z1, Z2 and Z3. between low and high. Presently, American manufacturers of bearings are using the vibration acceleration value determine the quality of bearings that is merely a measure of the bearing's fatigue life.On the product body of the bearing each bearing will bear its own label, brand name and label. The bearing will be printed with the brand's labels, words, etc. The font on the product body is quite small, however the manufacturer prints the font using a steel printing technique and then emboss them prior heating. The font, although small, is very concave and, consequently, clear. The font on counterfeit products tends be unclear and floating due rough printing technique. Certain fonts can be easily erased by hand or the markings made by hand are not a good idea.

Bearings is utilized in an amount of various methods. You can find relevant slewing bearing of all useful sort together with name brand of bearings. However, good judgment could plays part. Discover more about this.The duration of bearing could be the volume of rotations bands makes in relation an added ahead of the exhaustion first occurs in single ring material or element rolling. Bearing life might be suffering from differences in making quality, uniformity associated with material in addition to. Even bearings of identical in size, made of the material identical made from the precise batch same have various lifespans due these distinctions.