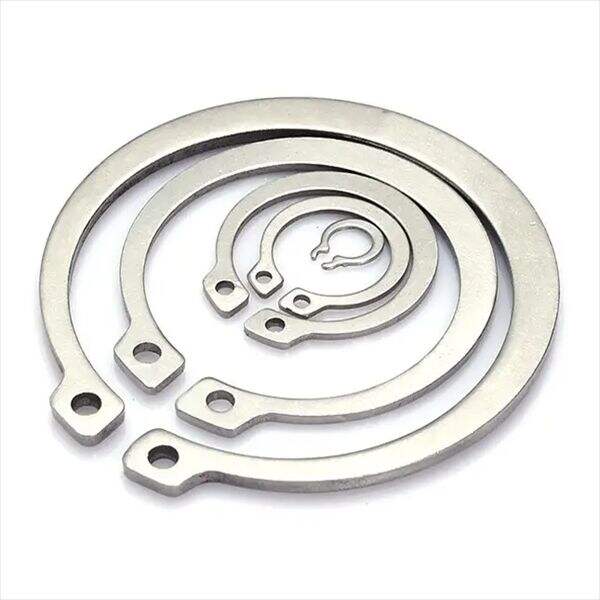

What is a Separate Retaining Ring?

A split band preserving is developed to suit into an item, such as a ray, avoiding it coming from moving far from an opening up or even every other orifice. The Yamei split retaining ring is split into 2 halves that are created towards suiting safely throughout the protest or even ray. The 2 halves occur in position through an area and its own little that enables all of them to press and keep the protest.

One of the most significant advantages of separate retaining bands is their specific effectiveness. They can be found in various applications, ranging from simple home repair jobs to complex industrial equipment. Yamei retainer are extremely durable and can withstand extreme temperatures and conditions.

Utilizing a separate retaining ring is simple. To set up a Yamei retaining ring, place one half of the ring on the shaft or material, and then move the other half across the shaft to its other edge. Next, use a pair of pliers to press both halves of the ring together until they securely hold the shaft.

To remove a separate retaining ring, use a pair of pliers to press both halves of the ring together until the gap within the ring opens. Then, slide the ring off the shaft.

For separate retaining bands, high quality is essential. The quality of the band determines its performance and longevity. It is important to purchase retaining bands from reputable manufacturers who use high-quality production processes and materials.

Along with quality, service is also important for separate retaining bands. A good Yamei shaft retaining ring manufacturer will offer excellent customer care, including quick shipping, easy returns, and helpful support.

This standard was formulated early. In determining the rate of vibration when split retaining ring rotate and the quality level is determined. It is divided in three quality levels Z1, Z2 and Z3. between low and high. Presently, American manufacturers of bearings are using the vibration acceleration value determine the quality of bearings that is merely a measure of the bearing's fatigue life.On the product body of the bearing each bearing will bear its own label, brand name and label. The bearing will be printed with the brand's labels, words, etc. The font on the product body is quite small, however the manufacturer prints the font using a steel printing technique and then emboss them prior heating. The font, although small, is very concave and, consequently, clear. The font on counterfeit products tends be unclear and floating due rough printing technique. Certain fonts can be easily erased by hand or the markings made by hand are not a good idea.

There are also useful information on how select the brand and type of bearings. However, some common sense on bearings have bias or are not often considered or not considered, can plays significant role in the use of bearings. Learn more about this.Bearing life is the amount of rotations bands makes relative its split retaining ring before the first fatigue expansion occurs in one ring material or rolling element. Bearing life can be affected by variations in manufacturing precision, homogeneity of material as well as other factors. Even bearings identical in size and same material, and made by the same manufacturer will be different in terms of lifespan due these differences.

Modern mechanical equipment cannot be complete without bearings. Its primary function is supporting, that is, the literal meaning of it is support the shaft, but this is only a part of its function. Support it's primary purpose is take on radial load. It's also important know the use of it to secure the axis. It is one fixed axis, therefore it is able only rotate and control its axial and radial motion.Bearings are a crucial component. When the components of transmission (such as shafts) are directly in contact with the hole the resistance drive and wear is excessive, and the transmission is hard to change and the bearing is dependent on rolling contacts between components support transmission parts. This results in a low sliding resistance, lower energy consumption and an easier start.

Bearing is an important part of the mechanical system widely used by people. A significant indicator of bearing quality is the bearing's cleanliness. It is vital ensure an effective cleaning of the bearings during the process of production and use in order extend their lifespan.Bearings are crucial mechanical parts, widely employed in daily life. Cleaning of bearings is a crucial measure of the bearing's performance. To extend the lifespan of bearings it is essential to clean them thoroughly throughout production and use.Many friends know that the majority of newly purchased bearings are coated in grease, but the main purpose of grease is to protect the bearing from rusting and does not play any lubrication function, and bearings are especially easily covered in dirt and generally difficult to clean thoroughly. Even if you buy bearings that do not have lubricating oil for an extended period of time, they'll absorb dust from magnetism as well as airflow. After mixing water vapour, sweat and other liquids, in the gap between the ball and dust will accumulate in the bearing to form "dirt communities" that are "fatal" the bearing rotation.