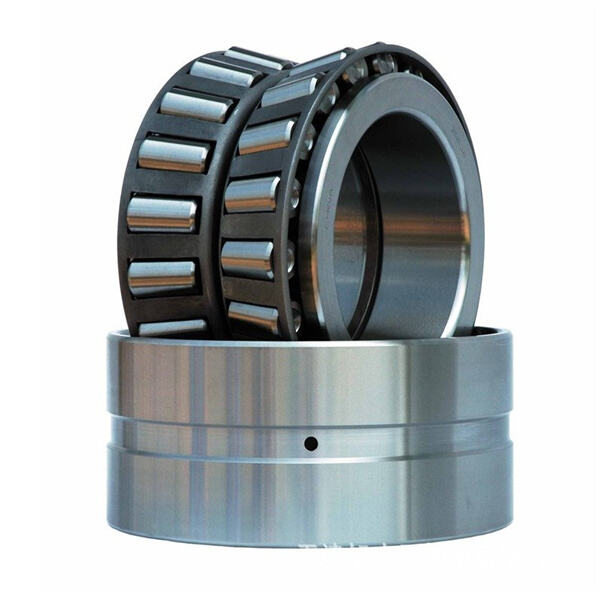

You might have found out about the term "double row tapered bearings" if you should be thinking about machines, or have ever used one it's a variety of bearing used in several devices, from vehicles to heavy-duty machines are industrial. We'll talk about the advantages, innovation, security, and exactly how to use Yamei's dvoredni konusni ležaj.

Double row tapered bearing have advantages over other bearings. One of the most benefits significant the capability to manage axial hefty. Axial loads are loads that work parallel to your bearing shaft. Because of their design, double row tapered bearings are designed for both axial and radial lots making them suited to devices which have both kinds of lots. An additional advantage of double row tapered bearing is the capacity to withstand conditions creating them suited to machines that operate in extreme temperatures. Yamei double line konusni valjkasti ležajevi are also lasting and durable. They will have a load high, this means they could handle lots hefty deforming or breaking.

Double row tapered bearings of Yamei have undergone innovation significant the years. Among the latest innovations could be the utilization of advanced materials, such as ceramic, to produce the bearings. Ceramic materials have high strength, wear resistance, and can handle temperatures being extreme. This makes them perfect for use in devices operate in harsh environments. Another innovation could be the usage of advanced manufacturing strategies, like laser precision and cutting casting, to create bearings being top-notch. These methods make sure that the double ležajni valjkasti konusni created to exact specifications, reducing the likelihood of defects and ensuring performance consistent.

Making use of Double row tapered bearing properly is essential to avoid accidents and downtime prolonged. You will need to make sure the bearing correct selected for the machine plus the load it is handling. Utilizing the bearing trigger wrong failure, it could end in costly repairs and downtime. It is important to ensure the double konusni potisni ležaj are installed correctly. Proper Yamei installation means the bearing runs at its highest possible and minimizes the risk of failure. It is essential to frequently maintain the bearings, ensuring they are lubricated and free of debris that will cause harm.

Double row tapered bearing such as in machines, gearbox, and axle assemblies. The Yamei bearings are found in pairs to take care of both axial and lots can be radial. They are also used to guide shafts rotating which ensures operation smooth of device.

Ležaj je sastavni dio moderne mehaničke opreme. Primarna funkcija ležaja je da podupire osovinu. Ovo je definicija u njenom doslovnom smislu, ali to je samo mali dio onoga što je njena primarna svrha. Njegova glavna namjena je izdržati radijalno opterećenje. Može se reći da se koristi za popravak osovine. Fiksirana je osa tako da može postići samo rotaciju, i kontrolirati svoje radijalno i aksijalno kretanje. Služi kao potpora, naime kada dijelovi prijenosa (kao što je osovina) direktno sarađuju s rupom, otpor vožnje je visok i habanje je veliko i prijenos je teško zamijeniti, a ležaj se oslanja na kotrljajući kontakt između komponenti pomaže u podršci komponentama prijenosa, tako da je otpor klizanja manji, sa manjom potrošnjom energije, a lako se pokreće i tako dalje.

The first standard was created in the early years. The quality of a double row tapered bearing is determined by analyzing the acceleration of vibration when the bearings are rotating. It is divided three different quality levels Z1, Z2 and Z3. between low and high. Currently, domestic bearing manufacturers still use the acceleration rate as a way measure bearing quality. It is a simple way measure the durability of the bearing.On the product body of the bearing, each bearing will have its own brand name, label etc. on the bearing product body. Although the font is very tiny, the bearings manufactured by formal producers make use of the steel printing technology print. They are embossed prior overheating treatment. Thus, even though the font is tiny it is very concave and extremely transparent. The font used on counterfeit goods tends be unclear and floundering due the rough printing method. Certain fonts can be easily erased by hand or the manual marks are serious.

Ležajevi se nalaze u različitim metodama će se razlikovati. Možete pronaći korisne uvode za odabir vrste ležaja. Ali dobro prosuđivanje je ključno. Saznajte više o temi. Životni vek ležaja može biti širok raspon okreta koje trake čine u vezi sa drugim ispred ekspanzije vrlo zamor prvo u proizvodu sa jednim prstenom ili valjkastim elementom. Na vijek trajanja ležaja mogu utjecati razlike u preciznosti izrade, homogenosti materijala i tako dalje. Jednake veličine ležajeva, isti materijal i izrađeni od potpuno iste serije, mogu imati različit životni vijek zbog tih varijanti.

Ležajevi su ključna komponenta mehaničkog sistema koji ljudi obično koriste. Čistoća ležajeva je važan pokazatelj performansi ležaja. Da bi se produžio životni vek ležajeva, neophodno je temeljno očistiti ležajeve tokom proizvodnje i upotrebe. Ležaj je jedna od najvažnijih mehaničkih komponenti, koja se intenzivno koristi u svakodnevnom životu. Važan pokazatelj kvaliteta je čistoća ležaja. Da bi se produžio životni vek ležajeva, ključno je efikasno očistiti njihove površine tokom proizvodnje i upotrebe. Većina ljudi je svjesna da su svi novi ležajevi opremljeni mašću. Mast se koristi samo za zaštitu ležaja od korozije i nije namijenjena za podmazivanje. Ležajevi takođe mogu biti izvor prljavštine i teško ih je temeljito očistiti. Čak i ako kupite ležajeve koji nemaju ulje za podmazivanje neko vrijeme, oni će apsorbirati prašinu kroz magnetizam i protok zraka. Zatim, kada znoj i vodena para u ležaju između kuglice, jaz će se povećati i formirati "zajednicu prljavštine" i predstavlja "fatalnu" rotaciju ležaja.