Knowledge of reducer oil seals and bearings

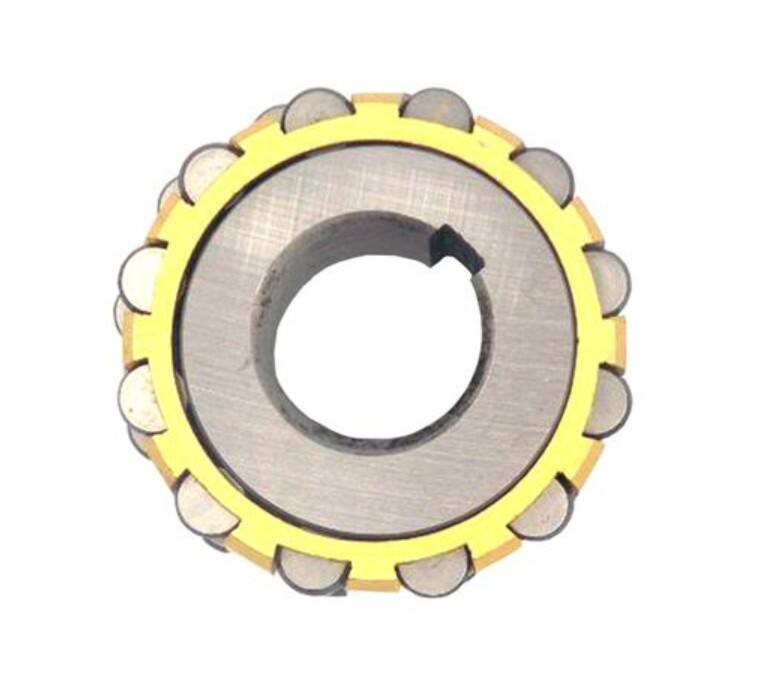

The function of the oil seal is simply used to seal the oil, and the purpose is not to let the oil inside the reducer leak out. The oil is the necessary liquid substance in the reducer transmission system, so the oil seal plays a role in the reducer to ensure that the oil does not leak out. The most common types of oil seals are split haplotype and assembled type. The output end and input end of the reducer have oil seal devices, and the longer the working time of the reducer, the oil temperature will also rise. The oil seal can protect the reducer bearing and oil leakage, so as to keep the reducer oil normal. Oil is a liquid substance, it is volatile, and the higher the temperature, the faster it evaporates. The oil quality and life of the reducer are directly related to the quality of the oil seal, so the good quality of the oil seal can improve the working time and life of the reducer. On the other hand, the oil seal also plays a role in preventing the waste of resources (oil) and the increase of costs when the reducer selection, the quality of the oil seal and its structure is one of the matters that must be understood. The above is a simple introduction to the role of the reducer oil seal, but also to understand from other aspects. Reducer bearing: There are many types of reducer bearings, commonly used rolling bearings and cylindrical roller bearings. There are many series of reducer bearings, such as SKF bearings, Fag bearings, NSK bearings, NTN bearings and TIMKEN bearings. On the one hand, the role of the reducer bearing is to keep the lubricating oil inside the bearing in use, to ensure that the bearing is in a lubricating state, and on the other hand, to protect the dust or harmful gases outside the bearing will not enter the bearing cavity to prevent damage to the bearing. The bearing can play a role in supporting the gear shaft or connecting rod between rotation in the reducer. In addition, the size of the deceleration model is different, and the bearing model is different. The reducer is a transmission mechanism that needs to transmit torque to the working machine through the shaft and bearing. Therefore, how the transmission efficiency and quality are directly related to the bearing, the sliding quality of the bearing and the life will affect the overall quality and performance of the reducer.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PL

PL

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

SQ

SQ

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

MK

MK

HY

HY

AZ

AZ

KA

KA

BN

BN

BS

BS

EO

EO

LO

LO

MN

MN

TE

TE

MY

MY

KK

KK

ST

ST